Advantages of the CINC technology

Advantages of the CINC technology

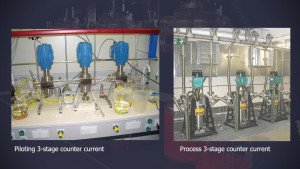

Applications which are presently running in mixer- settler, steered or pulsed columns can be optimised with the CINC technology. Our combined high sheer mixing and high g separation enable us to reduce product volume in the process, reduced space and reduced solvent required.

In many applications the CINC technology reaches a higher efficiency than other separation and extraction technologies. The special ability to intensive mix and to sharp separate in one unit makes the technology an ideal tool for liquid – liquid separation and extraction applications.

The main advantages are:

- Time saving due to combined mixing and separation in a continuous process

- Lab scale results can easily be scaled up to full process scale.

Small footprint even for complex counter current or cross current applications. - Immediate equilibrium due to intensive mixing small volumes mixed.

Very efficient use of water or organic solvents in washing or extraction applications. - High productivity because mixing and separation occur simultaneously.

- High energy savings on heated or cooled operations, due to small volumes.

- Easy process control results in a high and continuous product quality.

Reduced risk due to reduced volumes in the process. - CIP (clean in place).

- SIP (sterilise in place).

- Small holdup volume.

- Extraction direct out of the fermentation broth if DCM or Chloroform are the solvents.

- Different size centrifuges to enable an economic solution from 0 – 30000 l/h;

- ATEX conform.