Separation DF (direct feed)

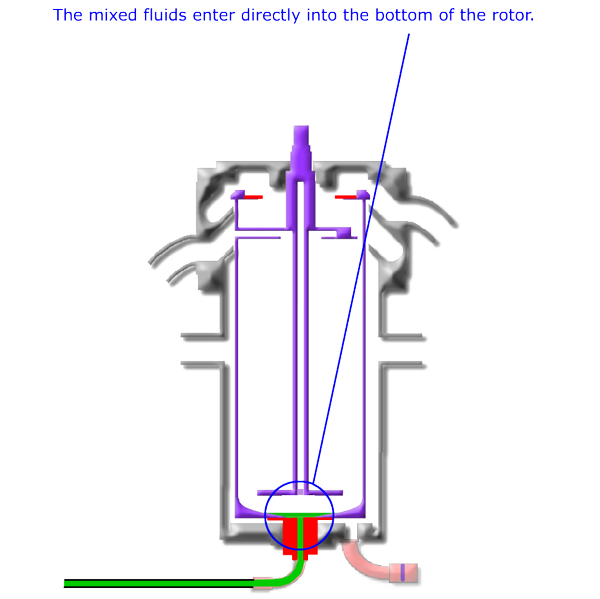

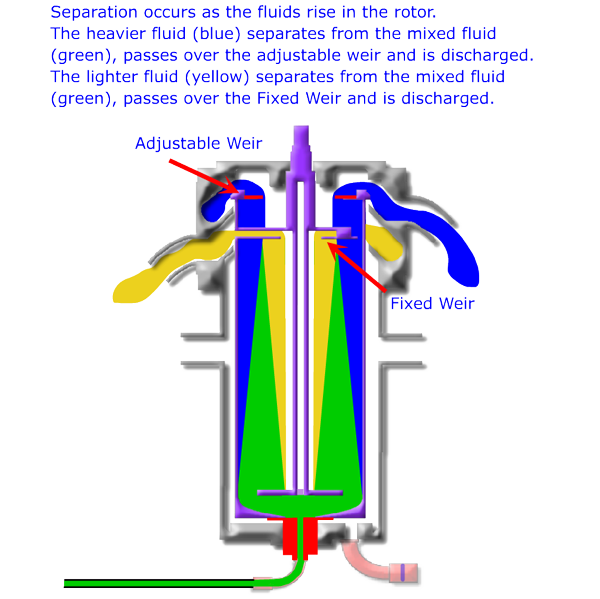

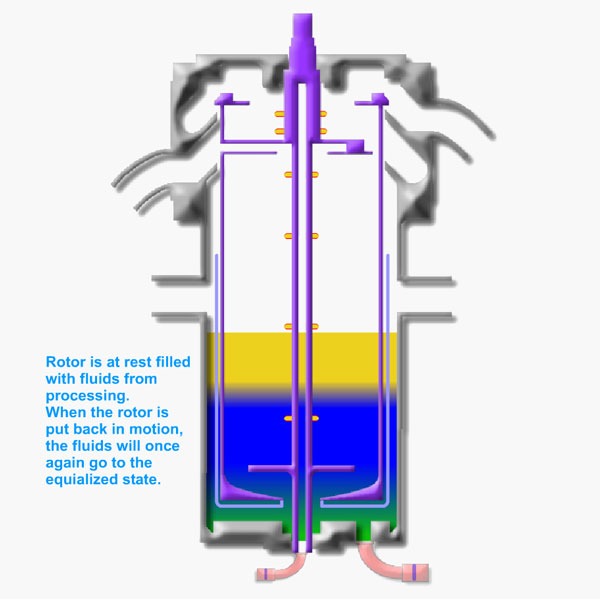

Direct feed minimises the sheer forces to the mixed fluid stream to enable an efficient separation.

The mixed fluid will be fed via the bottom inlet direct into the separation area inside the rotor.

Separation occurs continuously. This operation mode is ideal for liquids which tend to create emulsions.

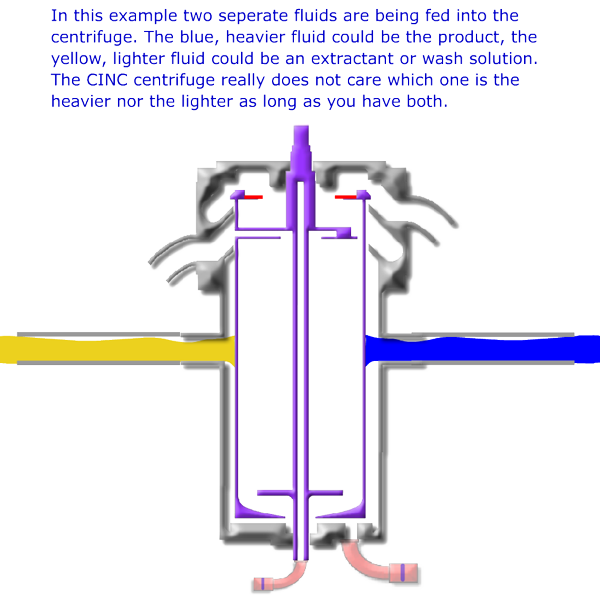

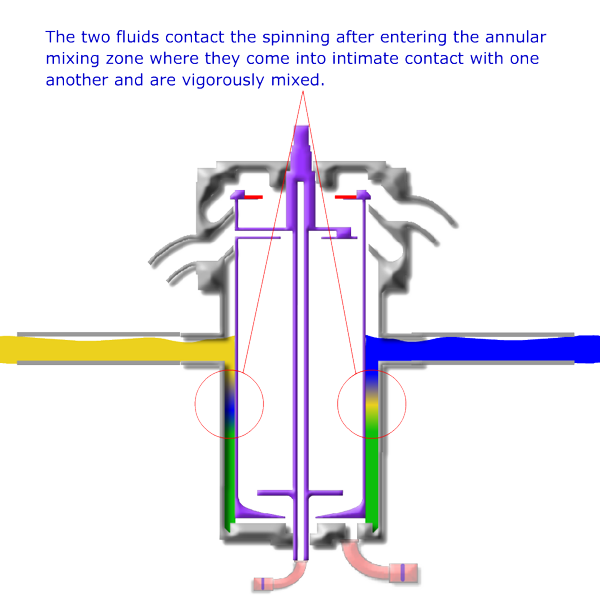

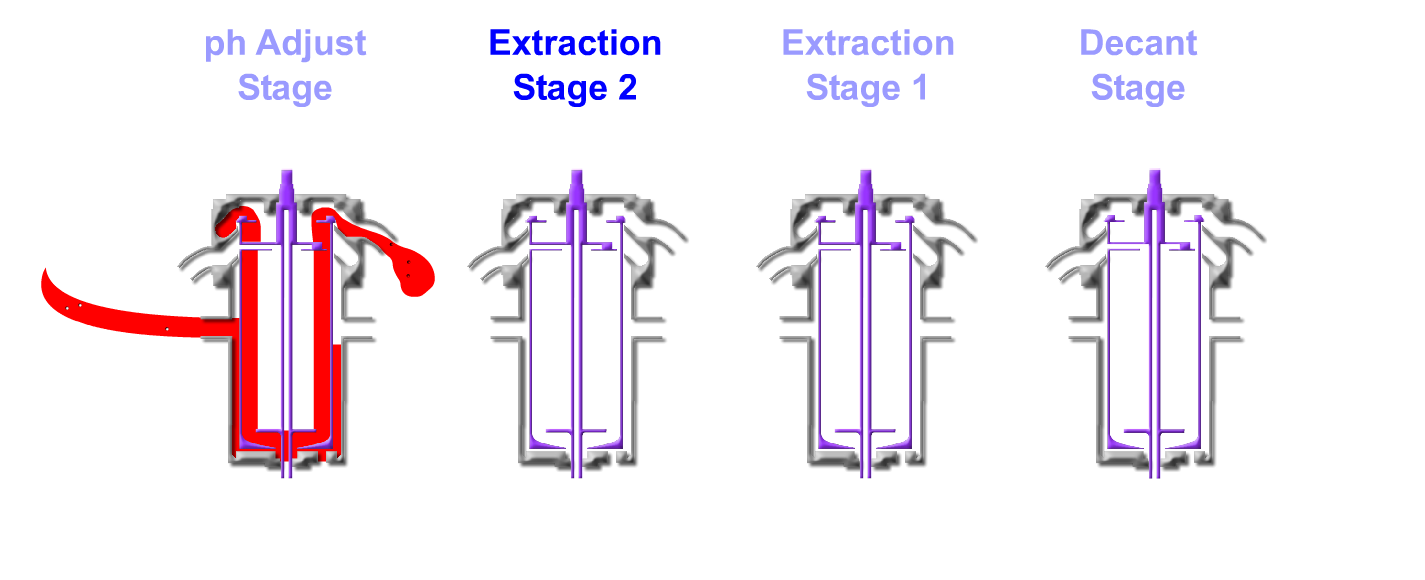

Extraction / washing:

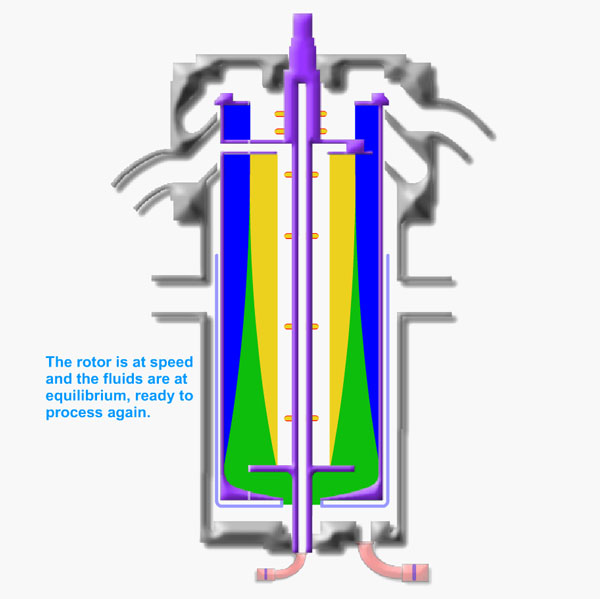

The mixing will be performed in the annular mixing zone between the spinning rotor and the housing wall.

Equilibrium will be reached after seconds. Special inserts optimise the mass transfer coefficient.

For reactive extraction the mixing time can customised.

Inside the rotor separation occurs continuously.

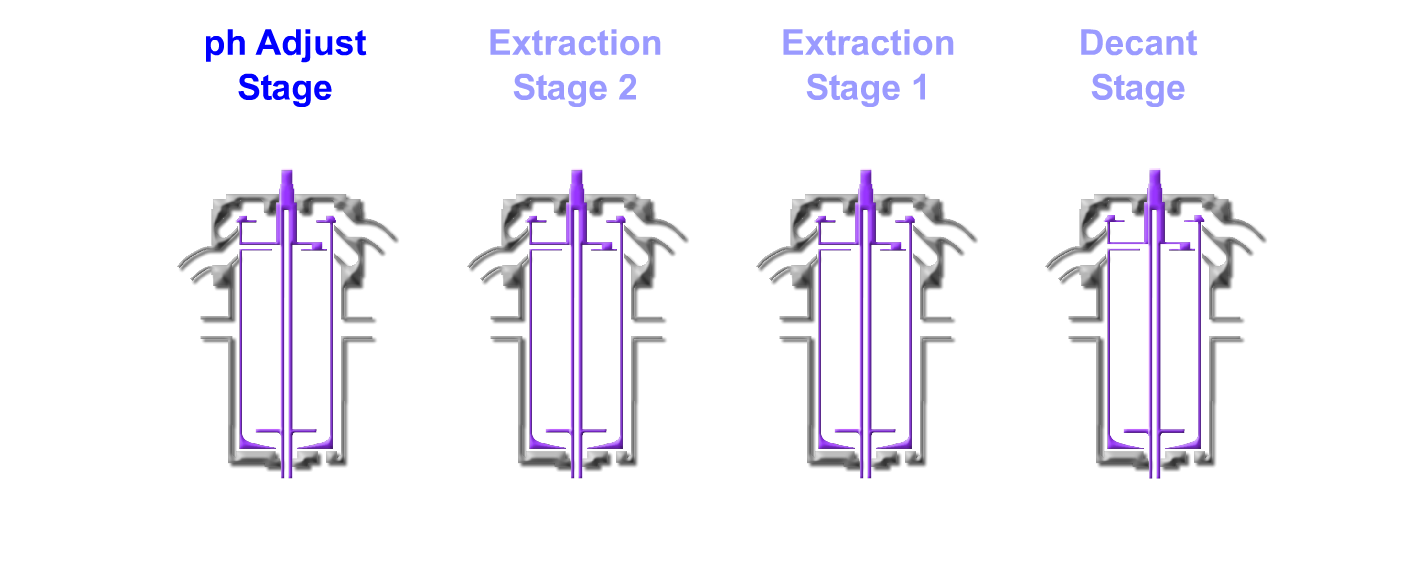

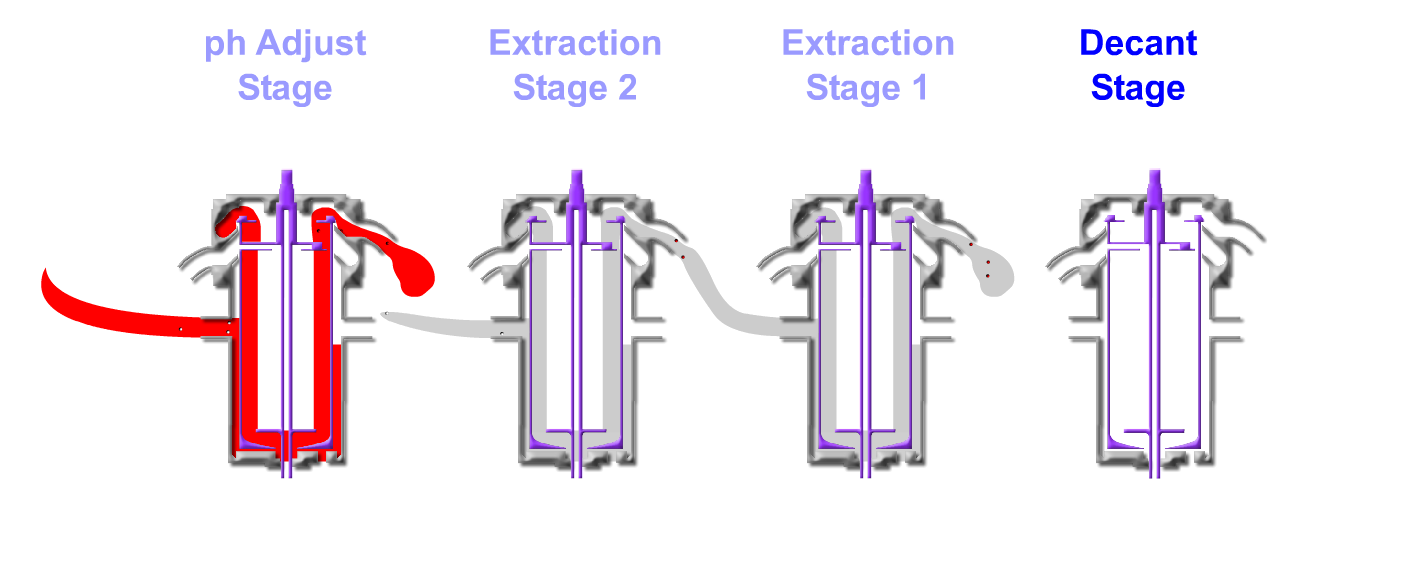

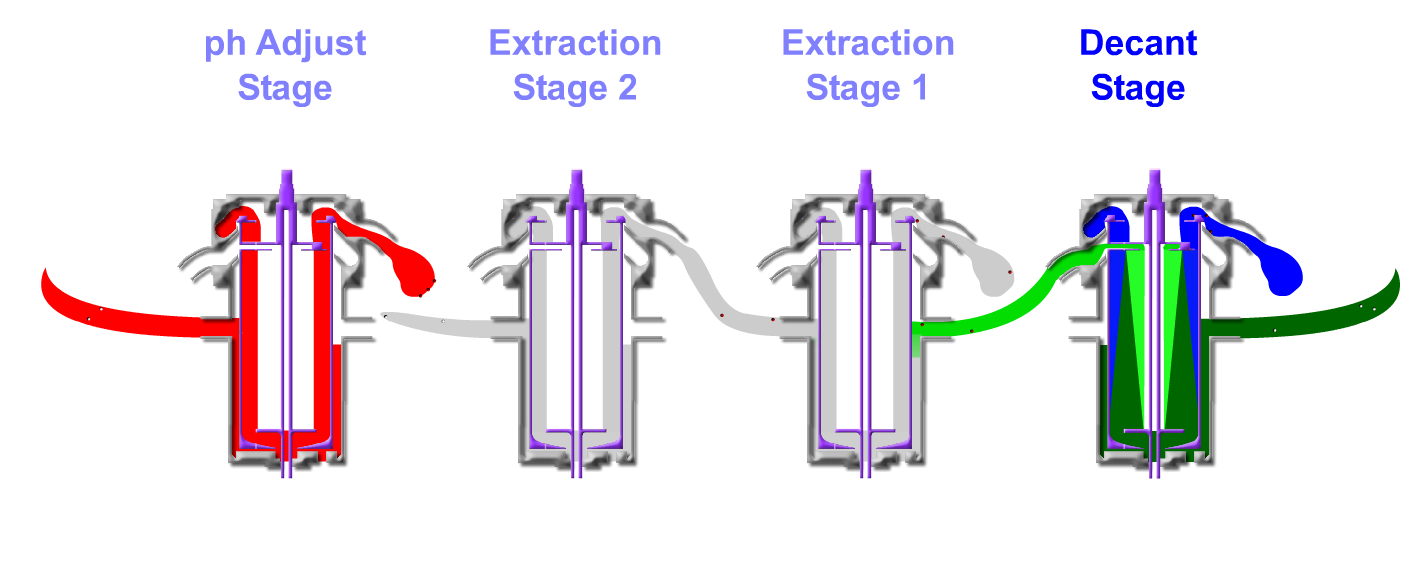

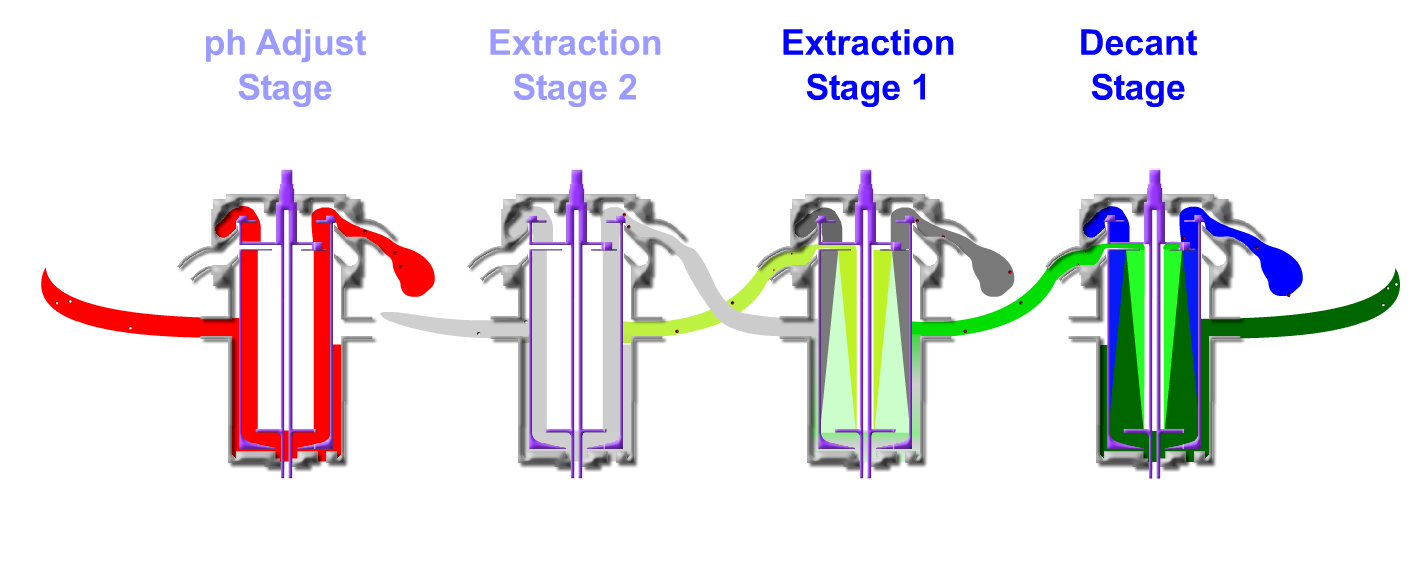

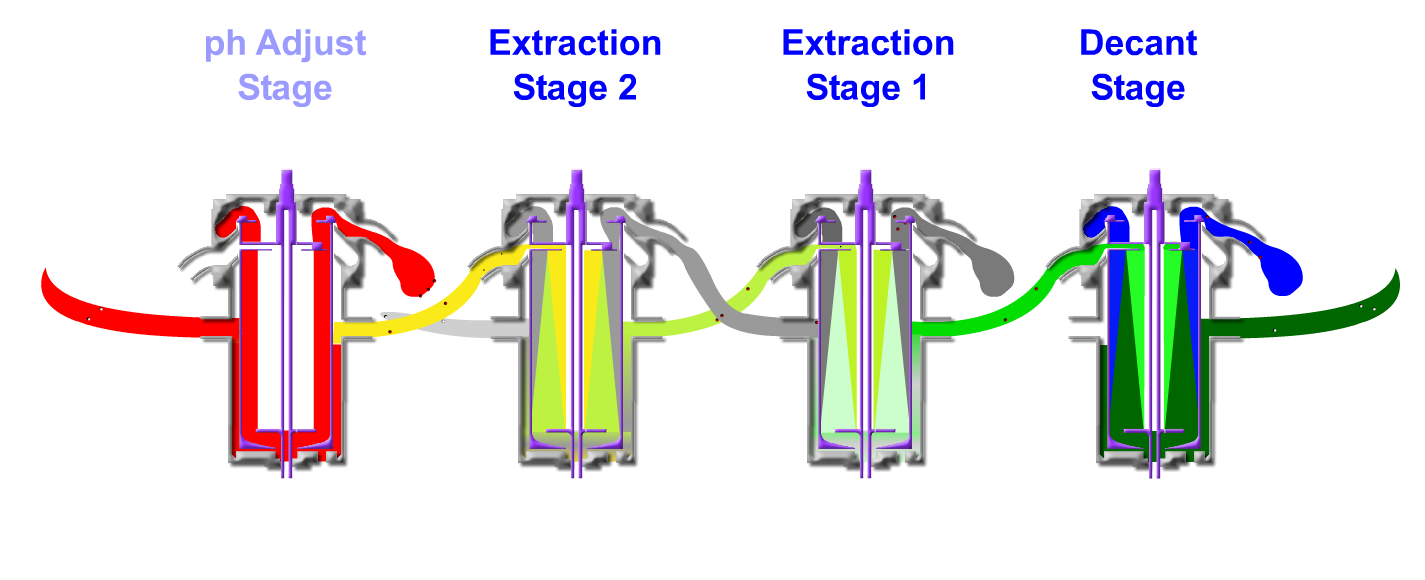

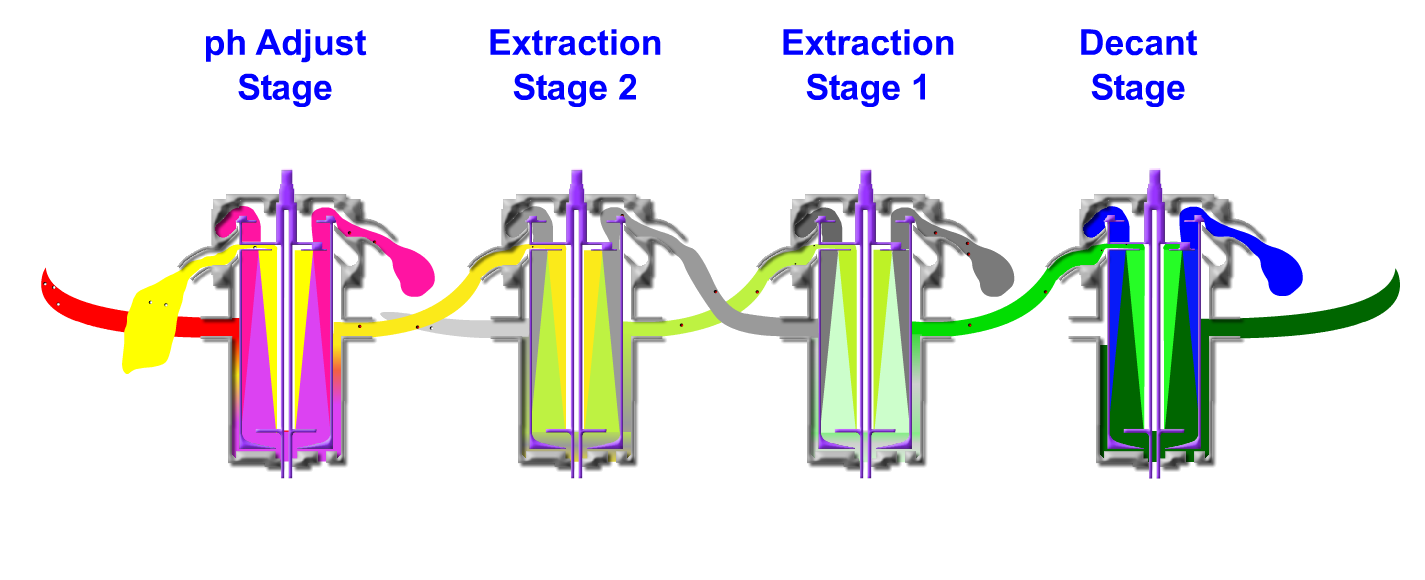

Multi stage:

Each centrifuge represents one theoretical stage, processes requiring a multi stage.

Counter current or cross current extraction are established with a series of centrifugal extractors.

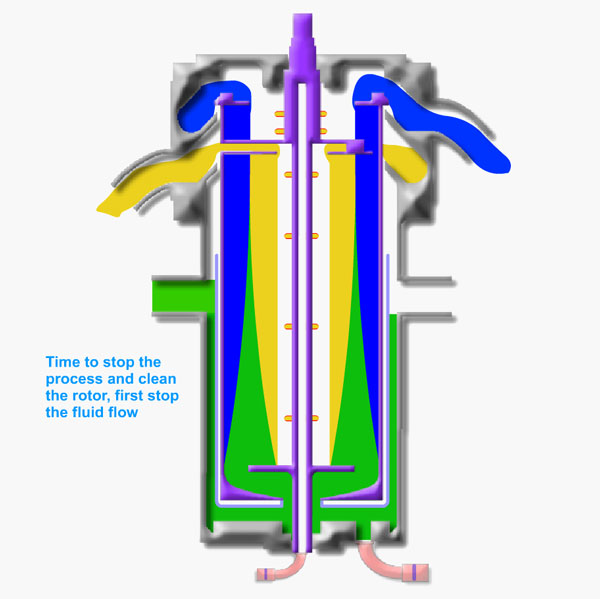

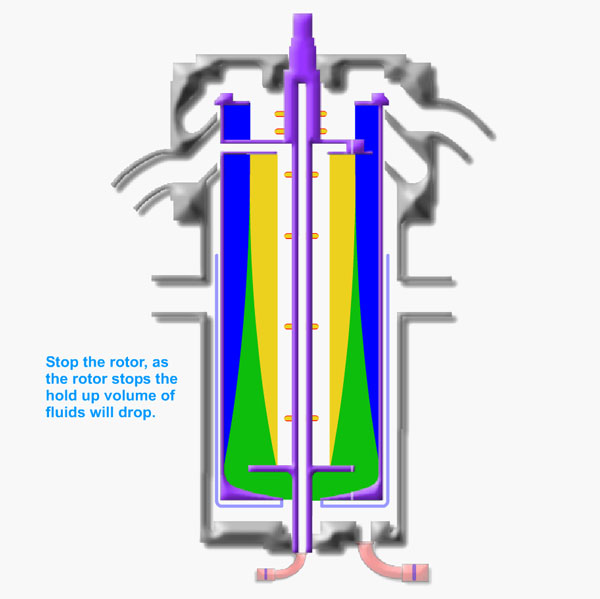

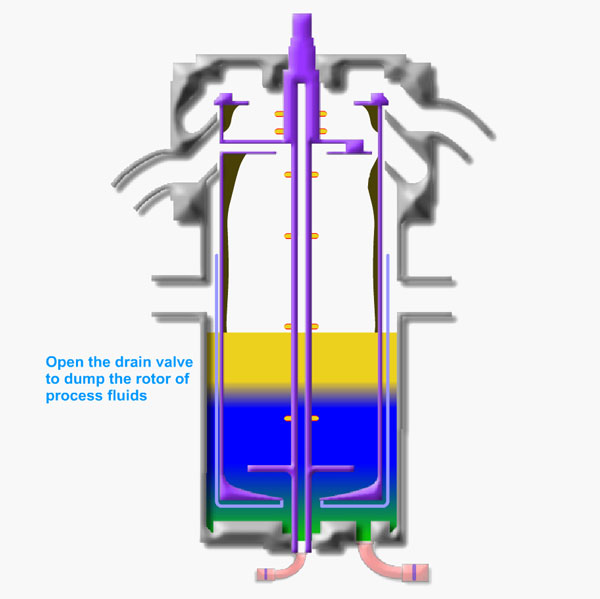

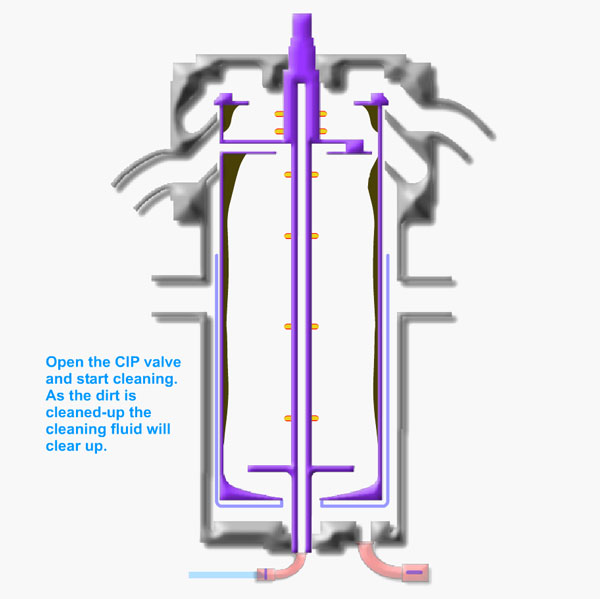

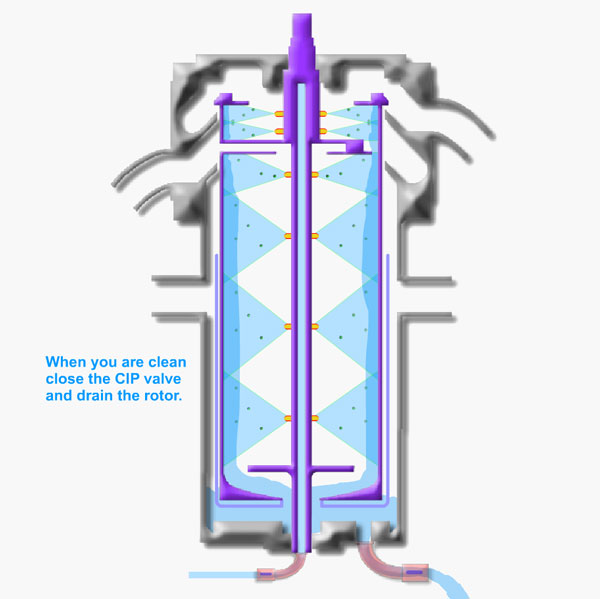

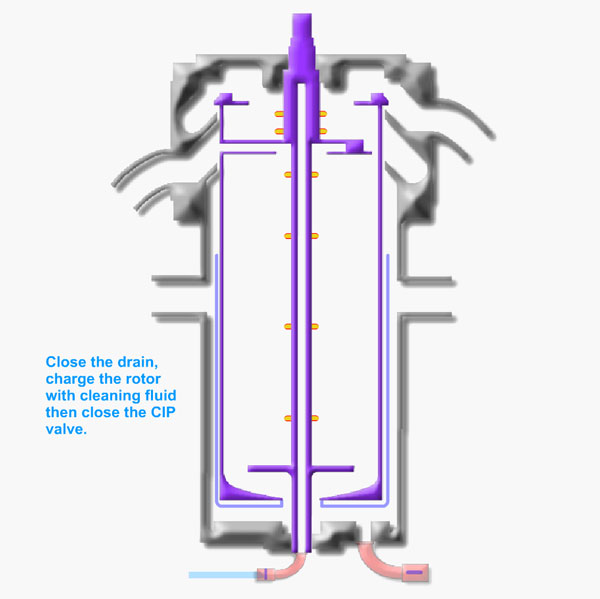

Clean in place CIP / Steam in place SIP:

An integrated CIP / SIP system is installed to cleaning the centrifuge without taking the machine apart.

Product overview

| Flow rate | L x B x H | Mass | |

|---|---|---|---|

| V02 / CS 50 | 0,01-1 l/min | 30x30x60 cm | 30 kg |

| V10 / CS 250 | 1,0-80 l/min | 70x70x170 cm | 400 kg |

| CS 330 | 1,0-160 l/min | 105x105x214 cm | 900 kg |

| V16 | 1,0 - 300 l/min | 112x112x230 cm | 1400 kg |

| V20 / CS 500 | 1,0 - 750 l/min | 120x120x260 cm | 2000 kg |

Materials of construction:

Stainless steel 1.4571/316Ti

Hastelloy C22

Seals: Teflon / FEP encapsulated / Kalrez